Características principais

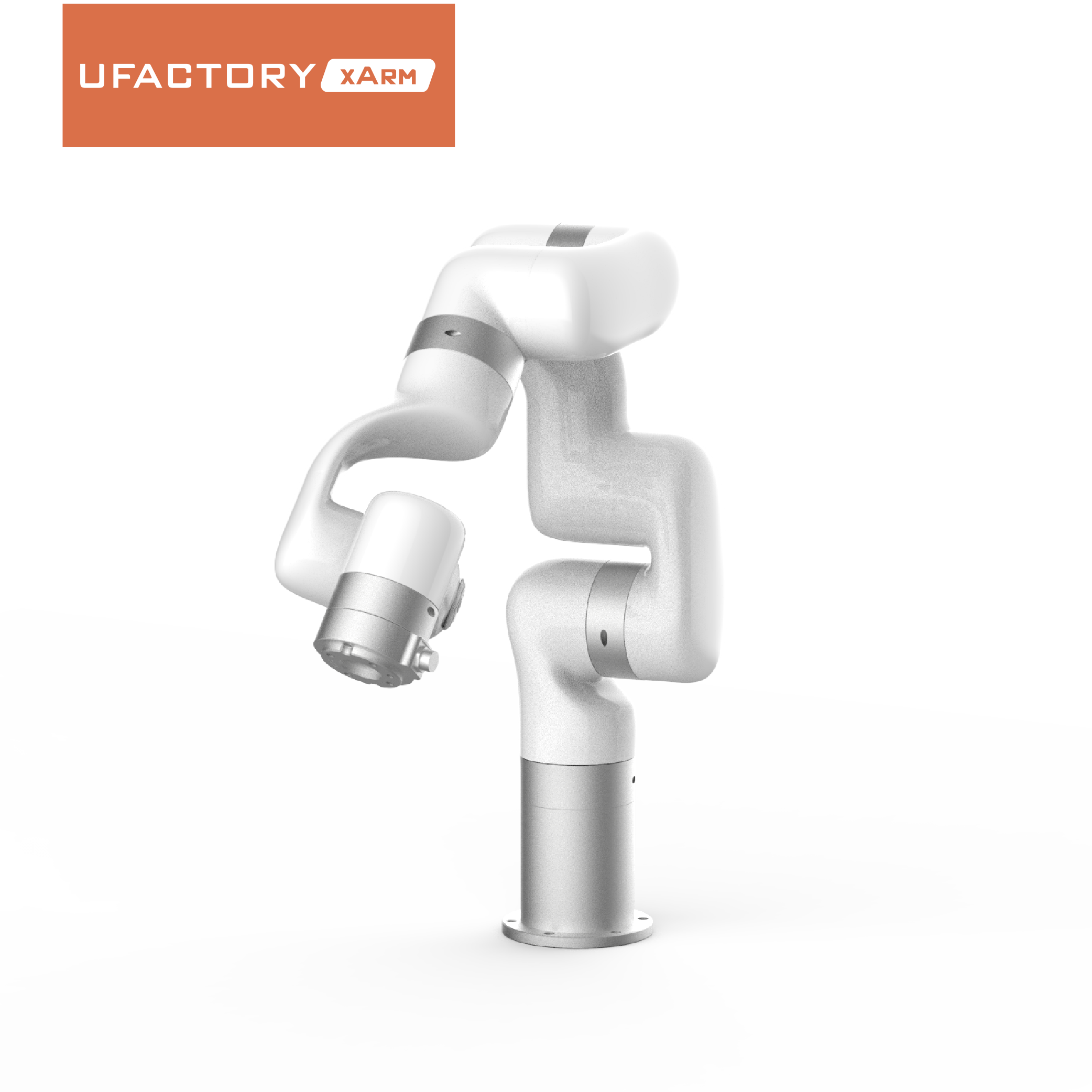

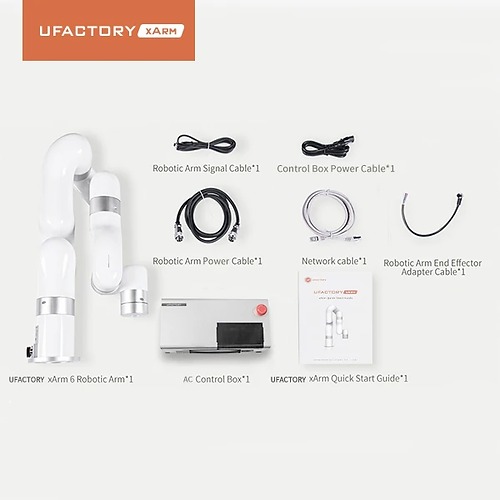

- Desempenho profissional: Ostentando um Capacidade de carga útil de 5 kg e um impressionante 2$\pm 0,1 \texto{ mm}$ repetibilidade, o xArm 6 oferece a precisão e a resistência necessárias para tarefas industriais exigentes.

- Alcance e liberdade estendidos: Com 6 graus de liberdade (DoF) e um Alcance de 700 mm, oferece um grande envelope de trabalho e flexibilidade para manobras complexas no espaço cartesiano, ideal para montagem, inspeção e manutenção de máquinas.

- Construção leve e durável: Feito de fibra de carbono e alumínio, o braço do robô é leve (aprox.5 $12.2 \texto{ kg}$), facilitando a implantação e reimplantação em diferentes estações de trabalho ou linhas de produção.

- Ecossistema de software intuitivo: O xArm 6 integra-se perfeitamente com Estúdio UFACTORY, um totalmente Interface gráfica do usuário (GUI) plataforma que simplifica drasticamente a programação por meio de recursos como arrastar e soltar e modo de ensino manual.

- Operação de alta velocidade: Capaz de uma velocidade máxima de 8$1 \texto{ m/s}$, ele mantém alto rendimento para operações rápidas, como pick-and-place.

- Flexibilidade de código aberto: Ele suporta integração flexível com um robusto e SDK de código aberto compatível com Python, C++, ROS e ROS2, permitindo que engenheiros e pesquisadores desenvolvam soluções de automação avançadas e personalizadas.

- Ampla adequação à aplicação: Projetado para confiabilidade e segurança, suas principais aplicações incluem:

- Escolha e coloque e movimentação de materiais

- Conjunto e atendimento de máquinas

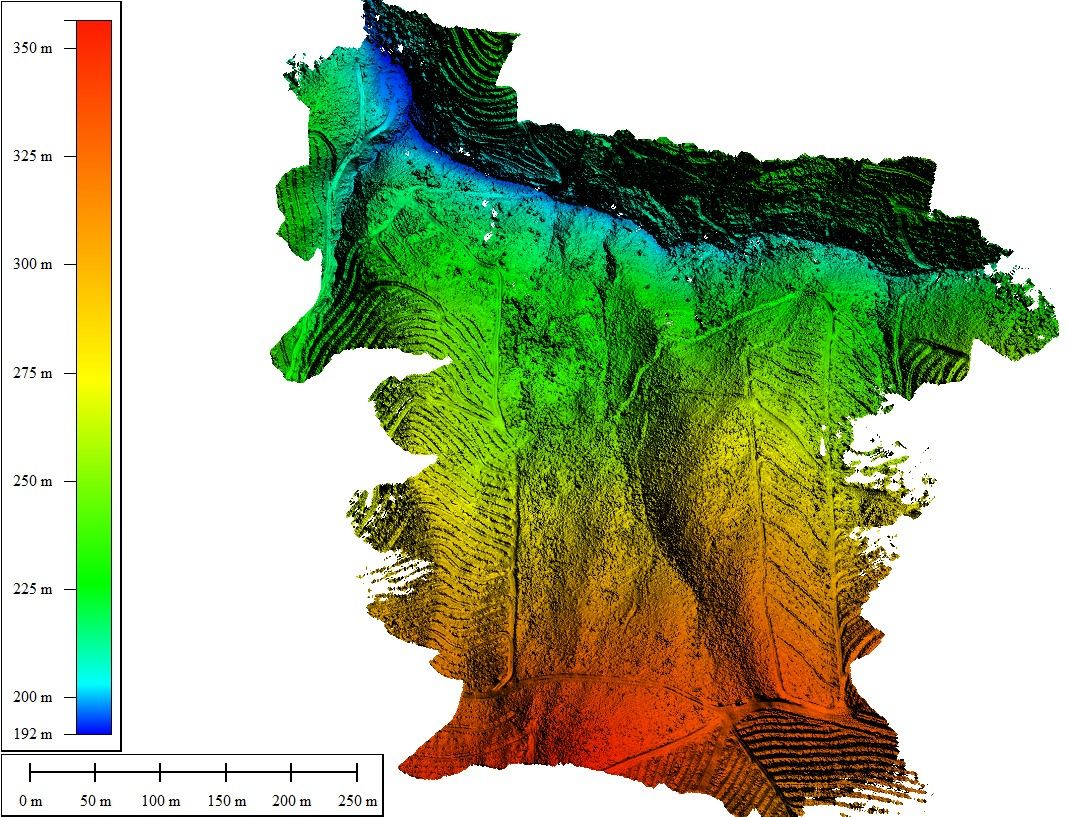

- Digitalização 3D e Inspeção de Qualidade (com sistemas de visão)

- Polimento, Rebarbação, Corte, e outros processos de fabricação.

- Segurança Colaborativa: O xArm 6 inclui detecção de colisão e foi criado para operar com segurança ao lado de trabalhadores humanos em um ambiente colaborativo.

O UFACTORY xArm 6 é a solução perfeita para empresas e laboratórios de pesquisa que buscam ampliar seus esforços de automação com um braço robótico confiável, preciso e fácil de usar.

Avaliações

Ainda não existem avaliações.