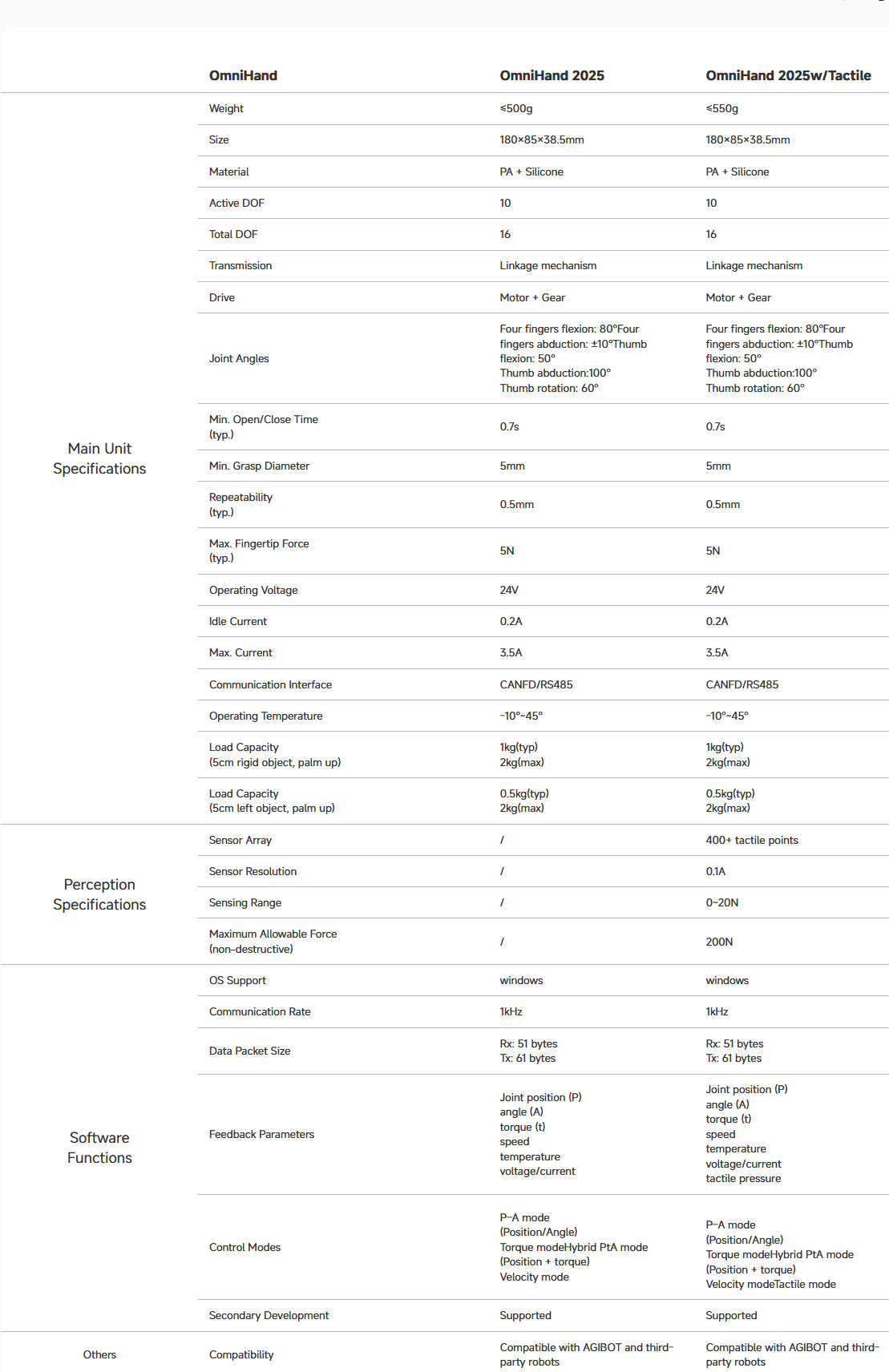

Key Models: Agile vs. Pro

The series is divided into two primary versions to suit different operational needs:

| Feature | OmniHand 2025 (Agile) | OmniHand Pro 2025 |

| Primary Focus | Interactive Services & Research | Industrial Precision & Heavy Duty |

| Degrees of Freedom | 16 (10 Active + 6 Passive) | 19 (12 Active + 7 Passive) |

| Weight | ~550g | ~800g |

| Max Fingertip Force | 5N | 20N |

| Tactile Sensing | 400+ Sensing Taxels | 150+ Multi-modal Taxels (3-axis) |

| Dimensions | 180 x 85 x 38.5mm | 207 x 98 x 56mm |

Core Features

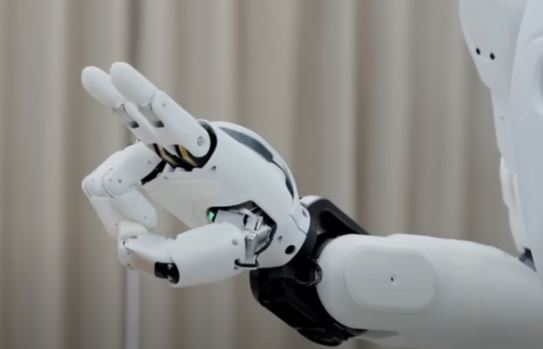

1. Human-Centric Dexterity

With up to 19 degrees of freedom, the OmniHand Pro can replicate complex human gestures, including delicate tasks like threading a needle or using professional tools. The “Agile” model even supports an exclusive back-of-hand touch interaction, allowing for more natural human-robot communication.

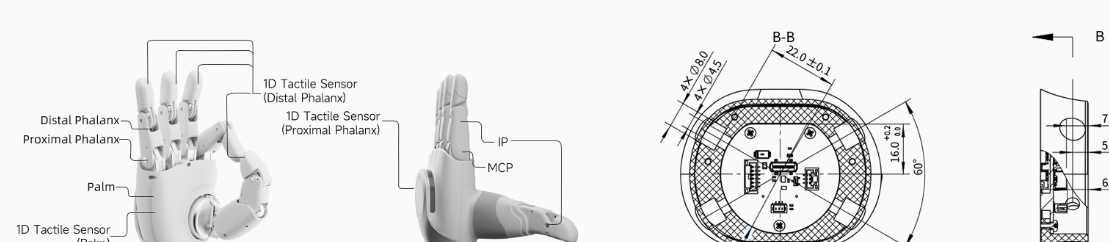

2. Exceptional Tactile Intelligence

Equipped with a high-density array of force sensors (up to 400+ taxels), the hand features 0.1N-level sensitivity. The Pro version includes 3-axis fingertip force sensing, enabling the robot to perceive normal and tangential forces—essential for “feeling” an object’s texture or slip.

3. Industrial-Grade Reliability

-

Anti-Pinch Design: Integrated safety features prevent accidental injury during human collaboration.

-

Extreme Durability: Tested for high-intensity tasks and capable of operating in temperatures ranging from -15°C to 50°C.

-

Plug-and-Play Compatibility: Supports CANFD and RS485 interfaces, making it compatible with most mainstream robotic arms and Agibot’s own G2 and A2 series humanoids.

4. Seamless Software Integration

The OmniHand 2025 comes with a robust SDK (C++ and Python), allowing developers to implement reinforcement learning and imitation learning algorithms quickly. It is fully integrated with Agibot’s ActionGPT, which translates voice commands into natural hand movements.

Application Scenarios

-

Commercial Services: Reception, gesture interaction (e.g., rock-paper-scissors), and document delivery.

-

Industrial Manufacturing: Precise sorting, assembly of small components (like RAM sticks), and tool manipulation.

-

Research & Education: A cost-effective platform for AI training, tactile feedback studies, and teleoperation.

-

Logistics: Handling diverse parcels of varying materials and sizes with adaptive grip strength.

Reviews

There are no reviews yet.