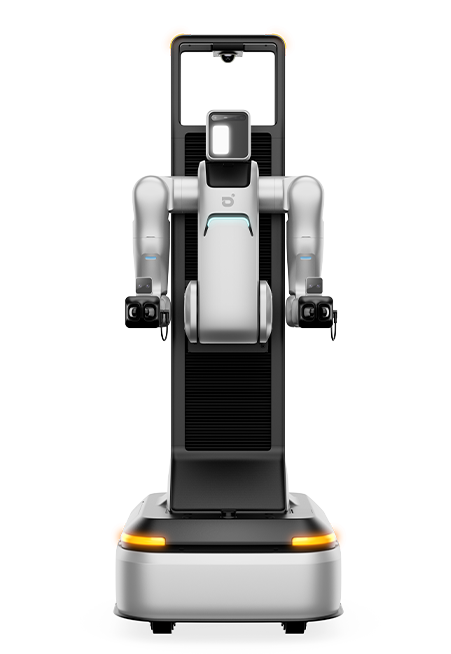

Agibot A2-W: The Flexible Manufacturing Specialist

The A2-W is defined by its “Embodied Intelligence,” combining high-precision dual arms with an agile wheeled base. It is designed to replace or assist humans in complex tasks like grabbing, precise plugging, component transporting, and asynchronous assembly.

Key Technical Specifications

| Feature | Specification |

| Height / Weight | 163 cm |

| Locomotion | 4-Wheel Drive (Crab-walking & Zero-turn radius) |

| Top Speed | Up to 5 m/s |

| Degrees of Freedom | 22 Total (7 DoF per arm + elevating/tilting waist) |

| Payload Capacity | 5 kg per arm |

| Battery / Runtime | 2 kWh / 5 Hours (Supports Hot-Swapping) |

| AI Computing | 275 TOPS (Embodied Intelligence) |

Core Features & Capabilities

-

Bionic Dual-Arm Collaboration:

Equipped with seven-degree-of-freedom arms, the A2-W can perform parallel or asynchronous movements. This allows for complex “hand-off” maneuvers and the ability to manipulate workpieces in mid-air with industrial-grade accuracy.

-

Superior Maneuverability:

The wheeled chassis supports 360° zero-radius turning and crab-walking. This allows the robot to navigate tight production lines and cluttered warehouse aisles much more efficiently than bipedal models.

-

Advanced Perception & Safety:

Safety is handled by a multi-sensor fusion system including 360° Lidar, four AI vision sensors (RGBD/Fisheye), and 6D force sensors. It features millisecond-level obstacle avoidance and arm-collision detection to work safely alongside human staff.

-

Rapid Task Adaptation:

Powered by Agibot’s self-developed ActionGPT and UniGrasp/UniPlug algorithms, the A2-W can learn to handle new objects or tasks within hours through 3D model synthesis and reinforcement learning.

-

24/7 Operational Readiness:

With a hot-swappable battery system and autonomous charging capabilities, the A2-W minimizes downtime, ensuring it stays on the line for multiple shifts.

Primary Use Cases

-

Electronics Assembly: High-precision plugging and component mounting.

-

Logistics & Sorting: Autonomous transport and organization within a factory ecosystem.

-

Industrial Inspection: Mobile monitoring with high-definition AI vision.

-

Laboratory Automation: Handling delicate samples and operating equipment.

Note: The A2-W is part of the broader Expedition A2 series. While the standard A2 is an interactive service robot (bipedal), the A2-W is the heavy-duty industrial “workhorse” of the family.

Reviews

There are no reviews yet.